How Cold Foil Can Change A Direct Mail Campaign

What Is Cold Foil

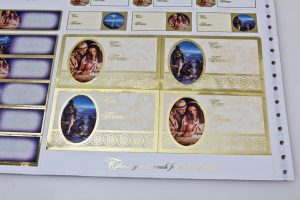

Cold foil is a cost-effective printing process in which a foil is applied to a substrate prior to the printing inks being applied. Cold foil creates a certain shine that can help an image pop and stand out when it is applied. Cold foil prints are typically varnished as well to provide a durable surface over the cold foil and ink. The registration between the cold foil, inks, and varnish will always be perfect because they are all affixed using a printing plate.

Quick Cold Foil Facts:

- Cold foil can be used on substrates such as:

- Pressure Sensitive Labels

- Coated Paper

- Paperboard

- Film

- Plastic

- Tube

- Shrink Film

- Heat-sensitive Material

- Inks that can used with cold foil include:

- Conventional Inks

- Hybrid Inks

- UV Inks

Cold foil will help you differentiate not only through its visual embellishments but as well as in its efficiency and cost savings.

Benefits of cold foil:

- Cold foil design stands out and catches the eye

- Good value vs. cost ratio

- Cost savings and faster speed to market

- Unlimited run lengths are possible

- Recyclable

- Available in a variety of silvers, golds, and custom or stock holographic patterns as well as transparent patterns

- Applicable to many different types of designs

- Flexibility to produce large, solid areas as well as fine detailed areas

- Cold foil is applied selectively, eliminating the need for opaque white

- No temperature involved so substrate won’t be adversely affected

- No edge/image shadow marks on the back of the substrate

- Cold Foil printing is done all in one inline process on the press

Limitations of cold foil:

- Cold foil is not applicable for absorbent or uncoated substrates

- Cold foiling requires complete cleanliness to minimize surface defects

- Cold foils typically are not available in deep shades

- Embossing/debossing must be done post-press

- Cold foil has a lower brightness level, depending on the surface properties of the material, print quality of the adhesive and the varnish

- Depending on the size of the area being cold foiled there could be more waste

How can cold foil increase direct mail response?

Embellishments drive higher direct mail response rate; that is a cold hard fact. Cold foil is an embellishment, another cold hard fact. See where we are going here? The thing is, it is a common misconception to think adding value-added services such as cold foil and other embellishments to your direct mail material is too expensive and out of reach. In reality, the return on investment is right there. The enhanced presentation of your brand will increase brand recognition and the customer’s perceived value of your brand. This will deliver you a greater return on investment and justify your slight added spending.

Cold foil is cost and time efficient. Because all its processes are inline you won’t be needing to wait a substantial amount of time longer than you would if used no embellishment at all. Once you begin to see the positive effects of tasteful embellishments it will become a staple of your direct mail strategy. A white paper titled “Transforming Direct Mail with Print Embellishments” published by the Foil & Specialty Effects Association shares some insights into the power of embellishments in the direct mail space.

“A great example of a distinguished direct mail piece is one done for the University of Wyoming, which includes both die cutting and raised spot UV coating. A local college added soft-touch coating and unique die cuts to a 2019 promotional brochure that led the school to achieve an 18% increase in enrollment. The school was searching for new ways to creatively and effectively reach people. Embellishments are effective in accomplishing that.”

Our advice is to test it out first before making the plunge. Run some A/B testing with your next promotional run, see if you can find a difference in impact for your business.